Handmade eyewear frames are revolutionizing manufacturing standards. Our role is to support eyewear manufacturers in pushing the boundaries of their creativity.

That’s why TCN offers adhesives specifically designed for assembling cellulose acetate.

We have developed two cellulose acetate adhesives in our laboratory in France: our cold adhesive and our hot adhesive.

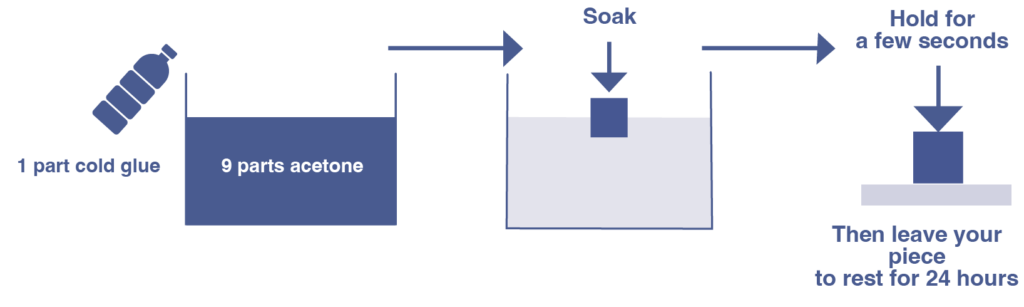

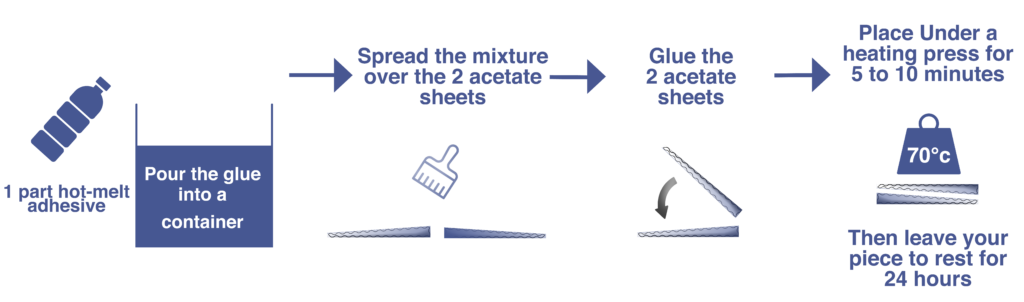

Discover the ease of use and effectiveness of our processes through the diagram below.

The cold glue must be diluted with acetone before use (see diagram above). The surfaces to be assembled are brought into contact with the glue for several seconds and then pressed together for a few seconds.

Cellulose acetate

1-liter plastic jerrican.

This glue is ready to use. Both surfaces are to be coated with a brush, roller, or gun. Once debubbled, the surfaces will be placed under a heating press at 70°C.

Immediately after bonding, they will be immersed in cold water to maintain flatness.

Cellulose acetate.

1-liter plastic jerrican.