Thermoformed plastic parts are dyed for practical and aesthetic reasons.

Our immersion dyeing ranges for these parts manufactured using various processes such as plastic injection molding, machining, or molding are developed in our laboratory in France.

We offer two ranges of liquid dyes: the universal GTC range and the high-performance GTD range.

Thermoformed plastic parts are dyed for practical and aesthetic reasons.

Our immersion dyeing ranges for these parts manufactured using various processes such as plastic injection molding, machining, or molding are developed in our laboratory in France.

We offer two ranges of liquid dyes: the universal GTC range and the high-performance GTD range.

Our GTC liquid dyes offer great flexibility in use.

Suitable for hot use, they are suitable for a wide range of materials, including ABS, Polyamide, Polyester, Polycarbonate, Acrylic, Carbon Fiber, PVA, PLA, TPU, and many others.

They meet almost all industrial requirements. Our concentrated GTC dyes offer a simple dyeing process suitable for a multitude of applications. In liquid form and easily diluted with water, our dye products allow for quick immersion dyeing, typically within minutes, of most plastics.

Whether for technical parts, luxury items, functional objects, or advertising creations, our dyes ensure coloration without altering the properties of the parts, regardless of their design.

Our dyeing process is cost-effective, whether for single parts or pre-series. Moreover, it helps to avoid common defects such as thickness variations, product dust, or detachment often encountered after paint application.

Acrylic (Plexiglas®, Altuglas®, etc.) is particularly appreciated by visual artists for creating unique pieces, trophies, POS displays, or decorative items. With our concentrated GTC dyes, PMMA, in sheet, rod, or tube form, can be produced in the desired color, offering great flexibility in creation.

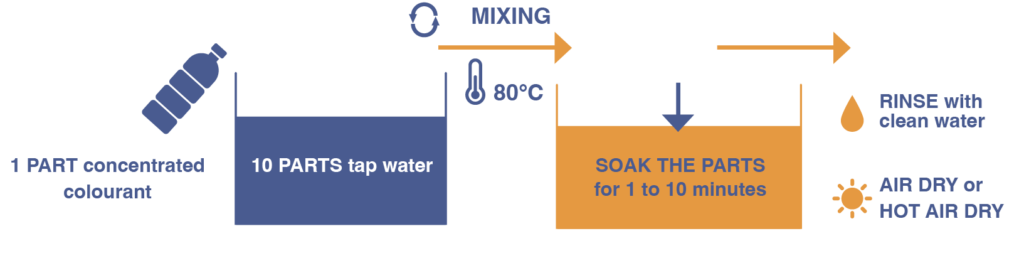

Discover the ease of use and efficiency of our processes through the diagram and videos below.

Universal GTC dyes are used for coloring a wide variety of thermoformed plastic objects.

They are designed to add color to finished parts in post-processing.

Thermoformed plastics.

30 standard colors mixable among themselves, for infinite color variations. Tinting service.

Plastic jerrican 1 liter, 5 liters, and 10 liters.

High-performance concentrated GTD dyes are suitable for coloring parts requiring UV resistance.

The GTD range offers high resistance to friction, sweat, and light. It meets the requirements for all outdoor projects.

Thermoformed plastics.

20 standard colors mixable among themselves, for infinite color variations. Tinting service.

Plastic jerrican of 1 liter, 5 liters, 10 liters.

Anti-UV 8630LC is an additive used directly in the dye bath,

increases the light resistance of dyed parts.

1 l, 5 l, 10 l

Bleach 4080, used pure when hot, removes non-conforming color.

1 l, 5 l, 10 l

Cleaner 7520B effectively cleans bins and utensils

1 l, 5 l, 10 l