Artisanal and custom eyewear manufacturing has historically developed in the Jura, a region in eastern France.

This craft combines industrial and artisanal expertise, which we have mastered through over 60 years of experience in this field. Our expertise enables you to achieve an infinite range of colors and even custom colors to support your collection creations.

TCN offers immersion coloring solutions for frames made from plastic materials used in both conventional processes and 3D printing.

In liquid form, our coloring products are preferably diluted with demineralized water. They allow for easy dyeing of cellulose acetate frames and various polymers used in additive manufacturing or injection molding, in just a few minutes.

We have developed two dye ranges in our laboratory in France: our TACC range for coloring cellulose acetate frames and our high-performance GTD range for dyeing frames made using additive manufacturing.

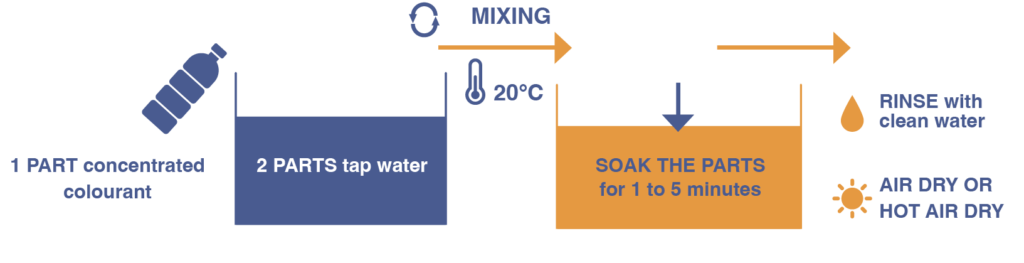

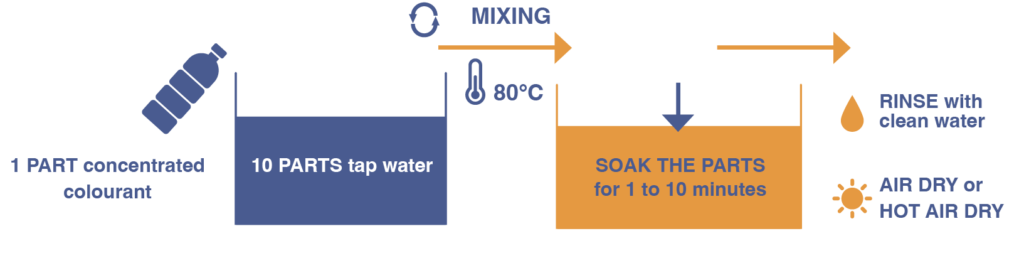

Discover through the diagrams and videos below the ease of use and efficiency of our processes.

TACC dyes custom color cellulose acetate and bioplastic-derived cellulose frames by simple dipping at room temperature. This process is particularly aimed at eyewear artisans for creating frame collections that set fashion trends.

Our TACC formulas, developed in our laboratory in France, ensure durable and uniform coloring, offering customization for your creations whose surfaces have been previously polished using our dry polishing process for cellulose acetate.

Cellulose acetate, bioplastic-derived cellulose

25 standard colors mixable with each other to create an infinite number of shades. Custom color service available.

1L, 5L, and 10L plastic jerricans.

High-performance concentrated GTD dyes are suitable for coloring eyewear frames made by laser sintering. The GTD range offers high resistance to friction, sweat, and light, meeting the demands of users and 3D printing specialists.

Thermoformed plastics from additive manufacturing

20 standard colors mixable with each other to create an infinite number of shades. Custom color service available.

Frames printed with Multi Jet Fusion technology can be dyed with shades marked “compatible MJF” on the GTD technical sheet.

1L, 5L, and 10L plastic jerricans.

It is possible to partially decolorize frames in a bath containing the colorless TACC 8280, pure or diluted, followed by rinsing with water.

1 l, 5 l, 10 l

–

1l, 5l

Bleach 4080, used pure when hot, removes non-conforming color.

1 l, 5 l, 10 l