Additive manufacturing is a technology adopted across various sectors including automotive, aerospace, marine, sports, and orthopedics. Initially used for prototyping, it is now widely integrated into production processes due to automation and the variety of available materials.

However, 3D printing materials offering a wide range of colors are scarce.

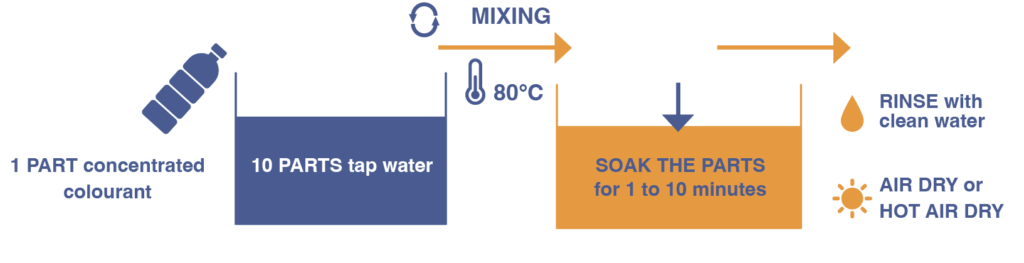

That’s why TCN offers immersion dyeing products for 3D printing thermoplastics. In liquid form, our dyeing products are used diluted with water heated to a temperature depending on the material being dyed. They allow easy dyeing in just a few minutes for most polymers: ABS, polyamide, PC, PVA, PLA, TPU. Moreover, they are compatible with all additive manufacturing technologies: MJF, SLS, SLA, FDM,…

We have developed two dye ranges in our laboratory in France: our universal GTC range and our high-performance GTD range.

Discover the ease of use and effectiveness of our processes through the diagram and videos below.

Universal GTC dyes are used for coloring parts made of plastics from additive manufacturing. They are designed to add color to finished parts in post-processing.

Plastics from 3D printing

28 standard colors mixable together, allowing for an infinite range of shades. Tinting service available.

Gray polyamide parts, Multi Jet Fusion process, can be dyed using shades marked “MJF compatible” on the GTC technical sheet.

Plastic jerrican 1l, 5l, and 10l.

High-performance concentrated GTD dyes are suitable for coloring laser sintered parts that require high durability.

In addition to the recognized qualities of universal concentrated GTC dyes, GTD dyes offer a high level of resistance to abrasion, perspiration, and light. They meet a wide range of requirements and are used in demanding fields such as automotive, aerospace, orthopedics, prosthetics, eyewear,…

Matières plastiques issues de fabrication additive.

20 standard colors mixable for an infinite range of shades. Tinting service available.

Parts printed with Multi Jet Fusion technology can be tinted with shades marked “MJF compatible” on the GTD technical sheet.

Plastic jerrican 1l, 5l, 10l.

GTD blue 8889 blue food contact dye, used according to our specifications, complies with Regulation (EU) No 10/2011 on plastic materials and articles intended to come into contact with food.

Plastics from additive manufacturing.

Suitable for thermoformed polymer parts from 3D printing intended to be in contact with foodstuffs.

1 certified color.

Plastic jerrican 1l, 5l, 10l.

For dyeing small batches, you will need a 25-liter stainless steel water bath, an electronic heating and circulating head, and a dosing canister. Check out the demonstration video for more information.

Fully automated, all-in-one industrial system without intermediate handling

Pre-rinsing – dyeing – rinsing – heat drying in a single unit

A complete cycle for an HP Jet Fusion 5200 in less than 60 minutes

Discover the SCA Equipment Line by Oryx: Perfect for Additive Manufacturing Dyeing.

Our partner Oryx has developed the SCA equipment line, offering an exceptional level of agitation and temperature control that makes these thermostatic baths the ideal tool for dyeing all types of objects produced through additive manufacturing using our dyes. The agitation ensures uniform and flawless dyeing, while the constant temperature guarantees repeatability across batches.

For industrial production runs, we recommend that you contact our German partner, Schmitt Ultraschalltechnik GmbH (SUT), which offers a range of specialized dyeing equipment. Please refer to the SUT Dyeing Systems brochure to find out more about the equipment available: https://www.schmitt-ultrasound.com

Anti-UV 8630LC is an additive used directly in the dye bath,

increases the light resistance of dyed parts.

1 l, 5 l, 10 l

Bleach 4080, used pure when hot, removes non-conforming color.

1 l, 5 l, 10 l

Cleaner 7520B effectively cleans bins and utensils

1 l, 5 l, 10 l